| |

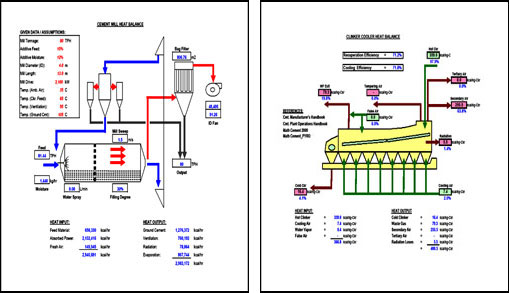

PLANT PROCESS-ENGINEERING OPTIMIZATION WORKS:

|

|

Plant economics would dictate that the unit cost in producing a certain product should be as

low as possible without compromising the required quality and standard. Meaning, that it is

always desirable to optimize the plant-process-engineering in order to achieve the lowest energy

cost at optimum production levels. And that Techkonsultancy, Inc. has proven its experience and

expertise in this field via careful investigation of existing plants in coming out with a simplified

modification to achieve a significantly lower specific energy consumption per unit of production.

|

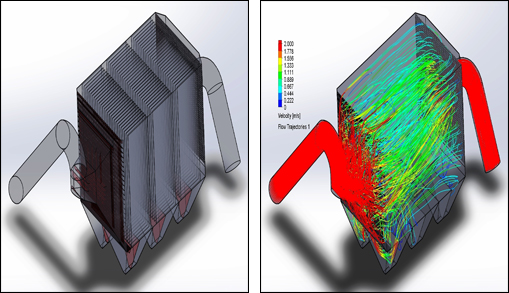

COMPUTATIONAL FLUID DYNAMICS (CFD) SIMULATION:

|

|

Our specialized CFD simulation works covers fluid-flow, thermal, and multi-physics applications.

Most of our completed works, during the last 16 years, have had evolved around fluid simulations;

purposely to find ways in optimizing the flow pattern in a given design e.g. hoods, ductwork or

ducting configurations, settling-chambers &/or pre-collectors, gasflow distribution profiles in

plenums and across modules such as in an EP/ESP units, as well as in large

cooling system of power stations among others, etc.

|

ELECTROSTATIC PRECIPITATOR GAS-DISTRIBUTION STUDY:

|

|

Optimum performance of an EP/ESP also depends with the proper balancing of the airflow to achieve

a reasonable particle residence and corresponding treatment time. Our actual field experiences

have had confirmed moderate to considerable deviations of the existing profile versus the

original design. Therefore tests and subsequent corrective measures appear necessary in cases

where performance of an EP/ESP need to be optimized. Our GD strength relied with

the +25 years of experience of our senior engineers.

|

ELECTROSTATIC PRECIPITATOR PERFORMANCE EVALUATIONS:

|

|

The overall assessment-program is geared towards the proper identification of the concerns

associated with the performance of the existing EP/ESP unit. Not just the typical parts replacement

approach but a more thorough process or system-based periodic performance evaluation of the

precipitator, which should help address and anticipate costly problems along the way. The key

is in-depth engineering evaluation that will address both the short-term and long-term goals

directed towards system-optimization.

|

EP/ESP TECHNICAL DIRECTION WORKS - REPAIR OR NEW INSTALLATION:

|

|

Our experienced partners and engineers could also help and act as 3rd-party consultants in

the preparation of methodologies, program-activities, as well as in providing the day-to-day

technical direction e.g. during repair, upgrading, or installation of new EP/ESP units; along with its

adjoining system components. To date, all of our site project management contracts have

always been completed in advance or at least within the allotted shutdown duration taking into

account the needed commissioning thereafter.

|

ELECTROSTATIC PRECIPITATOR CONVERSION INTO BAGFILTER:

|

|

Due to more stringent environmental regulations, overtime it may appear that keeping the existing

EP/ESP unit would no longer be practical. Therefore and is considered as the "last option",

converting the same into a more dependable Bagfilter may just be a fast turnaround solution.

Low emissions and at acceptable pressure-drop guarantees should be the norm of a properly engineered conversion.

Our seven consecutive conversions, within the same cement plant group, is a testament to this assertion.

|

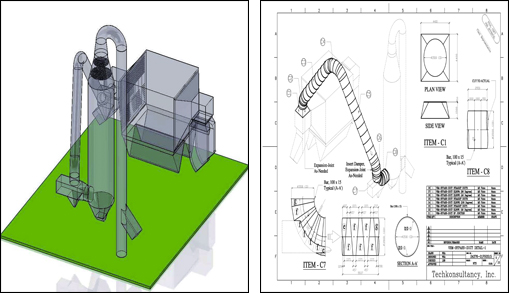

DUST COLLECTION SYSTEM DESIGN (HOOD TO EXHAUST FAN):

|

|

Our company is also into the business of detailed engineering in the design of complete dust

collection system; beginning from the pick-up hood, corresponding ductwork/s, and up to sizing

of the appropriate dust-collection-equipment e.g. pre-collector settling chambers and cyclones,

bagfilters, or even electrostatic precipitators (EP/ESP). It is necessary that the overall system is

harmoniously designed, to within reasonable energy requirement, and should likewise

avoid bottleneck sections along the vent route.

|

INDUSTRIAL VENTILATION SYSTEM PERFORMANCE AUDIT:

|

|

A persistent APC concern would fundamentally need either a sectional or plant-wide system

review and/or audit works in determining the suitable venting beginning from specific pick-up point,

the corresponding hood, ductwork, and DC-equipment. Basically, this is an engineering or

system-design review to arrive at an ideal setup vis-a-vis the existing layout and its associated

concerns. The concept is to optimize the process and at the same time comply with the needed

emissions standard set either by the in-house policies or by the government environmental regulations.

|

TRAINING & SEMINARS (FOCUSED ON DESIGN FUNDAMENTALS):

|

|

More often than not, a good measure of the APC-equipment operational reliability is simply

commensurate with the level of understanding and/or the competence of the concerned plant

personnel. Maintenance or management of an industrial ventilation system is no exception.

Therefore, training of the engineers and associated personnel is necessary to help optimize the

system and likewise achieve long term reliability. Techkonsultancy, Inc. have had experiences,

with a number of industrial plants, in conducting customized training program best suited for its specific application.

|

|

|

|

|